The lamps have a rubber boot on the back that contains the wiring. This WILL short out sooner or later due to vibration. There is NO FUSE protecting these lamps, instead a main fuse will blow and stop charging the battery. The rider will be aware of this when the battery dies and left on the side of the road. Regardless of lamps, INSTALL THESE!

My lamps died an early death by vibration. The clips that hold the Halogen lamp broke and Hella does not supply parts. A entire new lamp (pair) needs to be purchased. It's a better idea to switch to LED lamps as the engine vibration will continue to kill the bulbs anyway.

I changed mine to the Rigid Dually 'wide' style with yellow covers. The lamps are BRIGHT and I sometimes get cars to flash brights at night. They have never done so with the yellow covers even if the covers don't lower light output that much. Not being noticed, even during the day, is not an option. This is a very helpful upgrade.

Anyone who may want the yellow/amber look all the time may want to buy the lamps with amber LEDs and forgo the covers. The covers clip on the outside edge of the lamp and can rattle over time, again, due to vibration. I fixed this by running a cable tie around the clips of the cover.

On the bike and lit up...

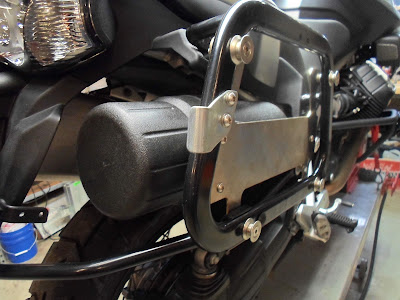

One problem...the stock brackets that the Rigid lamps ship with are the black ones in the above photo. The broken bracket is what happens after a few thousand miles of engine vibration. I had some alternate mounts made up while I was running a batch of TOOL TUBE mounts. The 12ga stainless bracket shown was cut by the laser cutter and bent up in the garage. They shouldn't have a problem staying in one piece now...

Doing this again, I would upgrade to the Dually HD or D2 HD with the more substantial mount that includes some vibration isolation. Another benefit is to have a more stout fastener that passes through the entire lamp. This controls the angle of the lamp and allows easier access while mounted on the bike. The standard D2 has captive nuts where the HD fasteners are accessible on both sides of the lamp.

Much improved design.

The Rigid Dually HD and D2 HD with the improved mounts.

The original Dually with the standard mount and captive nuts on my lamps shown above. This design is not suitable for the Stelvio on two points- the material at the lamp mount is too thin and the slot cut for the carriage mounting bolt provides too little surface area for mounting. My brackets fractured like the photo above AND at the base. I gave up and made my own per the above photos. The captive nuts are also limited on how tight they can be prior to rounding out the holes used to hold them. The through-hole of the HD mount is far superior.