AF1 stocks this item (LINKY)

All of the parts in the above kit can be sourced short of the stainless laser cut mount- The tool tube can be purchased at The Tool Tube (LINKY)

Alternative tube: Twisted Throttle (LINKY)

The hardware can be had from McMaster Carr from the following list. It's a bit overkill for what it's doing, but I changed out all my hardware to stainless on my racks (including the latch hardware). Substitute as your budget dictates.

Qty below is to replace hardware on both racks with stainless (spools and latch)

(5) Spool flat head socket cap screw, cross bar - M6 x 1 x 40mm #92125A248

(3) Spool flat head socket cap screw, solo spools - M6 x 1 x 35mm #92125A246

(3) Spacer between mount and rack - M6 x 3mm thick x 13mm OD #92871A740

(4) Latch mount button head cap screw, not required - M6 x 1 x 25mm #92095A242

(3) Tube mount button head cap screw - M6 x 1 x 16mm #92095A238

(3) Tube mount flat washers - M6 x 18mm #91116A150

(15) Nylock nut for all M6 fasteners - M6 x 1 #93625A250

About a 15 minute installation...

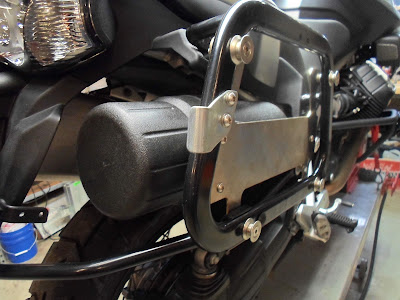

Plenty of room all round the tube.

Spools, spacers, nylocks, and now all stainless hardware.